Understanding Diaphragm Pumps: A Comprehensive Guide for Businesses

In today’s competitive landscape, businesses in sectors such as Auto Repair, Farm Equipment Repair, and Structural Engineering consistently seek innovative solutions to streamline operations, enhance efficiency, and reduce downtime. One such solution that has emerged as a vital component in various applications is the diaphragm pump. This article delves into the intricacies of diaphragm pumps, exploring their functionality, benefits, and applications, ultimately illustrating their importance to your business operations.

What is a Diaphragm Pump?

A diaphragm pump is a type of positive displacement pump that utilizes a flexible diaphragm to move fluids. The diaphragm oscillates between two chambers, creating a vacuum that draws the fluid in and subsequently forces it out through an outlet. This mechanism enables diaphragm pumps to handle a wide variety of fluids, including corrosive liquids, slurries, and viscous materials, making them essential in many industries.

How Diaphragm Pumps Work

1. The Basic Mechanism

At the core of every diaphragm pump is its diaphragm, which is often made from materials like rubber, plastic, or metal. The operation can be broken down into the following steps:

- Intake Stroke: As the diaphragm flexes upwards, a vacuum is created in the inlet chamber. This forces the inlet valve to open, drawing fluid into the pump.

- Discharge Stroke: When the diaphragm flexes downwards, the pressure in the outlet chamber increases, causing the discharge valve to open and forcing the fluid out of the pump.

2. Components of a Diaphragm Pump

A typical diaphragm pump consists of several key components:

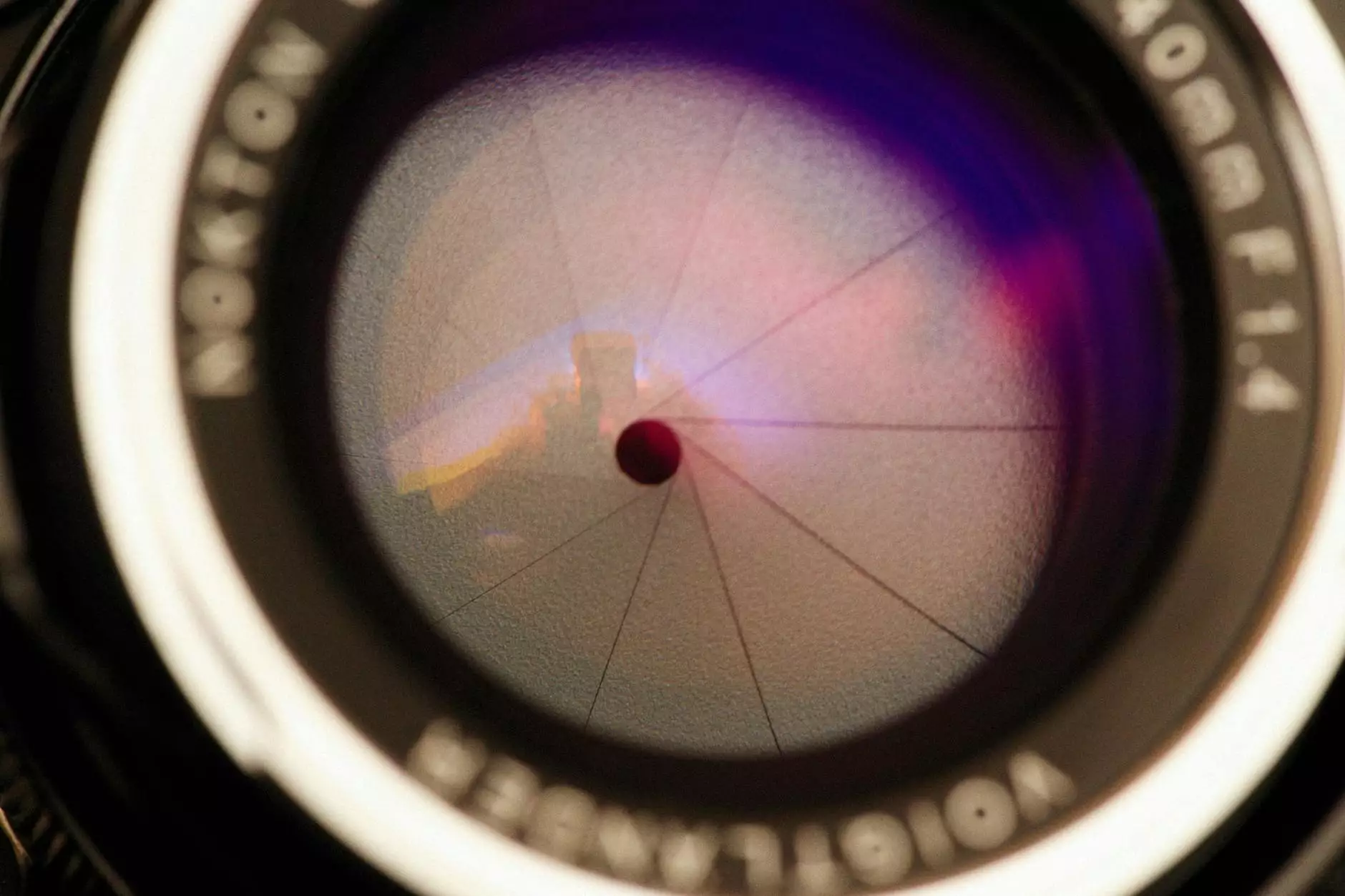

- Diaphragm: The main component that moves to create fluid transfer.

- Valves: Inlet and outlet valves that allow for unidirectional flow of the fluid.

- Actuator: Provides the motion necessary for the diaphragm movement, typically through mechanical or hydraulic means.

- Frame: Provides support and a structure for all components.

Advantages of Using Diaphragm Pumps

The adoption of diaphragm pumps comes with a myriad of advantages that can significantly enhance your business operations:

1. Versatility

Diaphragm pumps are exceptionally versatile, capable of handling various types of fluids, including:

- Corrosive chemicals

- Viscous fluids

- Slurries and solids

- Abrasive materials

2. Self-Priming Capabilities

These pumps can operate in low-level fluid conditions without needing priming. This feature is particularly advantageous in applications where reservoirs may not always be full.

3. Low Maintenance Requirements

Thanks to their simple design and fewer moving parts, diaphragm pumps require less maintenance compared to other pump types, leading to reduced operational costs.

4. Safety and Reliability

Diaphragm pumps prevent fluid leakage, making them a safe choice for handling hazardous materials. Additionally, their robust design ensures reliable operation, minimizing the risk of pumps failing during critical processes.

Applications of Diaphragm Pumps in Various Sectors

The versatility and effectiveness of diaphragm pumps allow them to be used across a multitude of industries. Here’s how they are effectively utilized in the sectors relevant to your business:

1. Auto Repair

In the auto repair industry, diaphragm pumps are used for:

- Fluid transfer of oils and lubricants.

- Emptying and filling tanks containing fuel or other fluids.

- Handling waste fluids for disposal.

2. Farm Equipment Repair

For farm equipment repair, diaphragm pumps provide reliable solutions for:

- Transferring pesticides, herbicides, and fertilizers.

- Water pumping for irrigation systems.

- Handling sludges and other viscous materials.

3. Structural Engineering

Within the realm of structural engineering, these pumps are essential for:

- Pumping concrete during construction.

- Managing fluids in various construction processes.

- De-watering applications on job sites.

Choosing the Right Diaphragm Pump for Your Business

Selecting the right diaphragm pump for your specific needs requires careful consideration of several factors:

1. Fluid Characteristics

Understanding the chemical and physical properties of the fluid you will be pumping is crucial. Factors such as viscosity, temperature, and corrosivity will influence your choice of materials and pump design.

2. Flow Rate Requirements

Determine the necessary flow rate for your operations. Diaphragm pumps come in various sizes and configurations to meet different flow demands.

3. Pressure Requirements

Consider the pressure differential needed for your applications. Ensure that the chosen pump can handle the required pressures without compromising performance.

4. Maintenance and Parts Availability

Look for models that offer ease of maintenance and where spare parts are readily available to minimize downtime in your operations.

Conclusion: The Future of Diaphragm Pumps in Business

As industries evolve, the role of diaphragm pumps becomes increasingly significant. Their adaptability, efficiency, and safety features ensure that they remain at the forefront of fluid handling technology. For businesses in Auto Repair, Farm Equipment Repair, and Structural Engineering, investing in diaphragm pump technology can lead to greater operational efficiency and enhanced performance.

Choosing the right diaphragm pump equipped with the best features suited to your specific needs will not only improve workflow but also contribute to the overall productivity of your business. As you continue to explore advances in pump technology, consider how diaphragm pumps can be integrated into your operations for optimal results.